I was 19 days over sixty when our first grandchild arrived. A respectable age to become a grandfather I thought to myself.

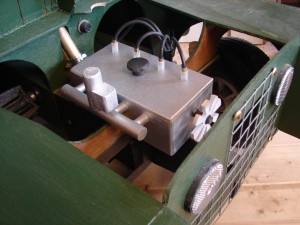

So what was Grandad going to make for this new addition to the family?

There is always something you remember from your own childhood and for me it was not having the one toy I really wanted, a pedal car.

pandora earrings,pandora necklaces,pandora essence, pandora jewelry,pandora jewelleryOil temperature is easiest to regulate in a deep fry setting, and you can get more done at once.. pandora jewelry,pandora charms,pandora bracelets,pandora rings.pandora earrings,pandora necklaces, pandora jewelry,pandora essence,pandora jewelleryAlzheimer’s disease represents another frequent cause of weight loss, especially among the elderly pandora sale. pandora jewelry,pandora charms,pandora bracelets,pandora rings.pandora earrings,pandora necklaces,pandora essence,pandora jewellerySAN FRANCISCO, CA JANUARY 28: Jude Siddall, owner of the Active Spaces in the outside courtyard at the Active Spaces located in the Mission district January 28, 2008 in San Francisco, California. pandora jewelry,pandora charms,pandora bracelets,pandora rings.pandora earrings,pandora necklaces,pandora essence,pandora jewelleryPeople with nickel allergies should ensure that they wear jewelry that is hypoallergenic, or nickel free. pandora jewelry,pandora charms,pandora bracelets,pandora rings.pandora earrings,pandora necklaces,pandora essence,pandora jewelleryTherese, Canada and Mexicali, Mexico pandora jewelry. pandora jewelry,pandora charms,pandora bracelets,pandora rings